Stability Matters

We all know the promise that CHO cells hold when it comes to therapeutic antibody development: scalability, high protein titers, and manufacturing potential. Yet, little has been done to characterize the physical stability of secreted antibodies from their inception during CHO cell line development, which leaves you with one option: stabilizing biologics that were not designed with aggregation in mind from the ground up.

For the first time, Aura immunoassays with particle characterization bridge the gap between cell line development and developability to allow pre-screening for antibody stability once mAbs are secreted from CHO cells. Characterization is fast, accurate, and detailed—no more lengthy analysis or prolonged wait times to get the data you need.

Measure Stability, Don’t Just Predict It

Have you been searching for an all-in-one protein aggregation and characterization particle analysis tool that includes advanced formulation characterization? With Aura, now you’ve found it.

Unlike products that simply use protein degradation metrics such as Tm to predict stability, our technology takes it one step further by measuring actual aggregation for stability, providing far more reliable insight into the product quality of your therapeutic antibody. With Aura, now you can truly understand the impact of proper biologics formulation on product stability.

Innovating For Biologics Developers

Identifying and quantifying particles is crucial to monitoring stability and promoting long-term efficacy in antibody therapeutic development. But with current analysis techniques, accurate particle identification is impossible. And if you’re using light obscuration (LO), you’re only getting part of the picture and likely missing subvisible particle count all together.

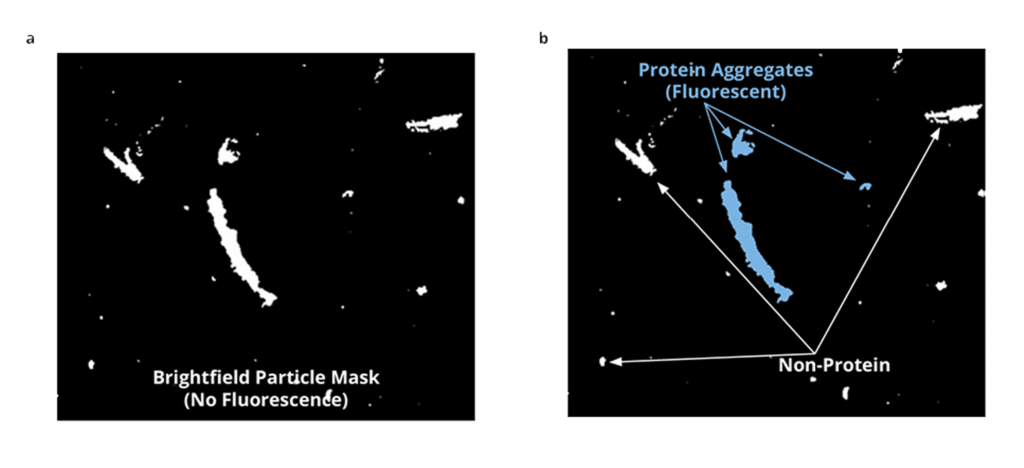

Aura instruments use Fluorescence Membrane Microscopy (FMM) a novel particle identification method that builds on Backgrounded Membrane Imaging (BMI) to identify, categorize, and scrutinize common particles in a sample by using extrinsic fluorescent dyes such as Thioflavin (ThT).

Now you can obtain protein/non-protein ID for a whole 96-well plate assay down to a single individual particle in less than 90 minutes.

Featured products

Frequently Asked Questions

Formulation of therapeutic antibodies involves designing a stable and efficacious dosage form suitable for administration to patients. This process includes selecting appropriate excipients, optimizing pH and tonicity, and ensuring compatibility with manufacturing processes and storage conditions. Key considerations in antibody formulation include maintaining protein stability, preventing aggregation or degradation, and minimizing immunogenicity. Common excipients used in antibody formulations include buffers, stabilizers (e.g., sugars and amino acids), preservatives, and surfactants (e.g., Tween and polysorbate). Formulation strategies such as freeze-drying (lyophilization) or liquid formulation may be employed depending on the desired dosage form (e.g., vials and prefilled syringes). Overall, a well-designed formulation is essential for ensuring the safety, efficacy, and stability of therapeutic antibodies throughout their lifecycle.

Antibody development involves methods aimed at generating antibodies with desired specificity and functionality for various applications, including diagnostics and therapeutics. Common methods include hybridoma technology, phage display, and recombinant antibody technology. Hybridoma technology involves fusing antibody-producing B cells with myeloma cells to produce immortalized hybridoma cell lines that secrete monoclonal antibodies. Phage display utilizes bacteriophages to express antibody fragments on their surface, allowing for the selection of antibodies with high affinity and specificity through biopanning. Recombinant antibody technology involves engineering antibody genes and expressing them in various host systems to generate antibodies with desired properties. These methods enable the generation of monoclonal or polyclonal antibodies against specific targets, facilitating research, diagnosis, and therapy in diverse fields.

Antibody production involves four main phases: immunization, cell fusion, screening, and antibody production. During the immunization phase, animals (typically mice or rabbits) are injected with the antigen of interest to stimulate an immune response and produce antibodies. In the cell fusion phase, antibody-producing B cells are harvested from the immunized animal and fused with myeloma cells to create hybridoma cells capable of producing monoclonal antibodies. The screening phase involves identifying hybridoma clones that produce antibodies with the desired specificity and affinity through techniques such as enzyme-linked immunosorbent assay (ELISA) or flow cytometry. Finally, in the antibody production phase, selected hybridoma cells are expanded and cultured to produce large quantities of monoclonal antibodies, which are then purified and characterized for use in research, diagnostics, or therapeutics.